Transforming Dry Leaves into Sustainable Paper

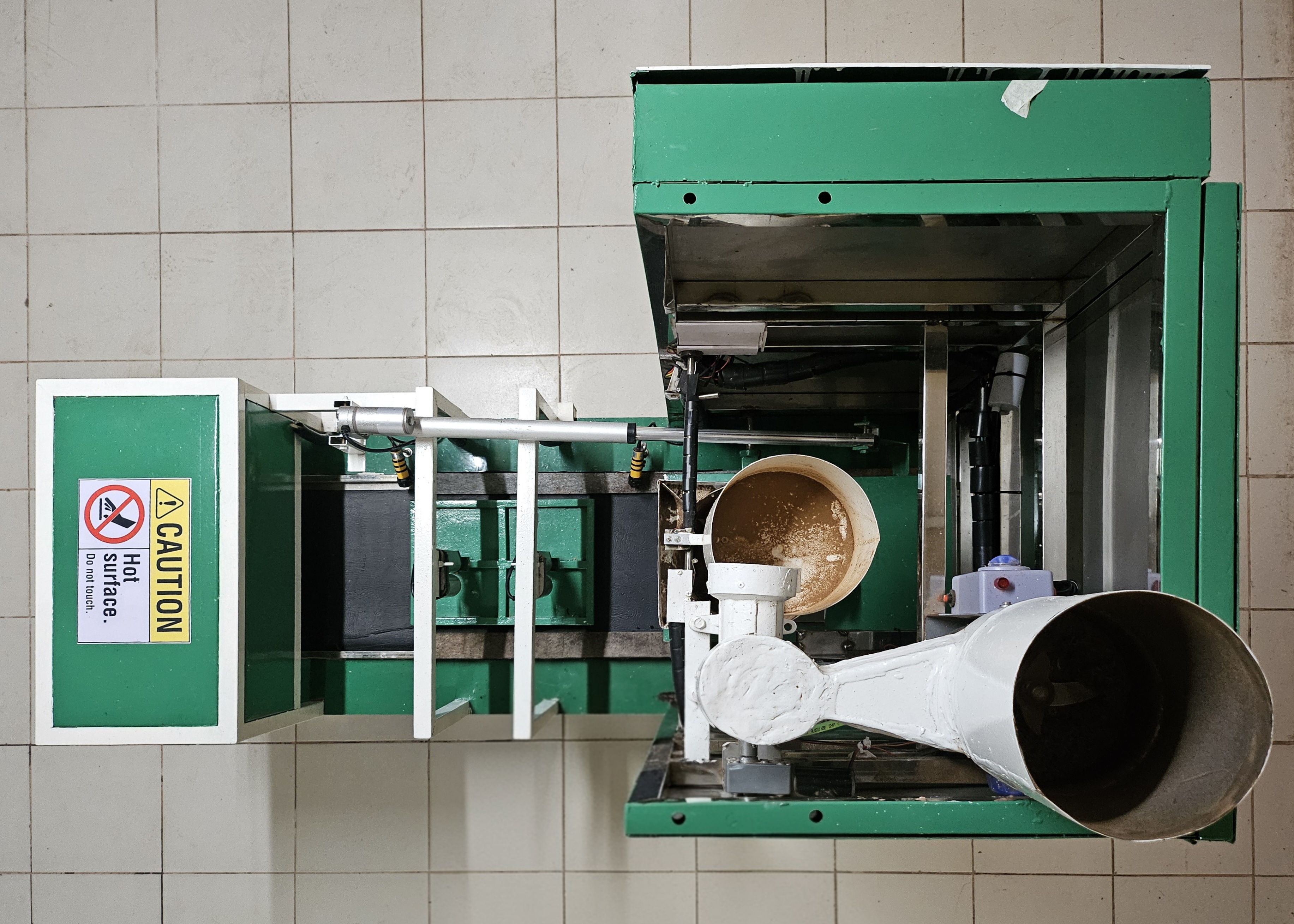

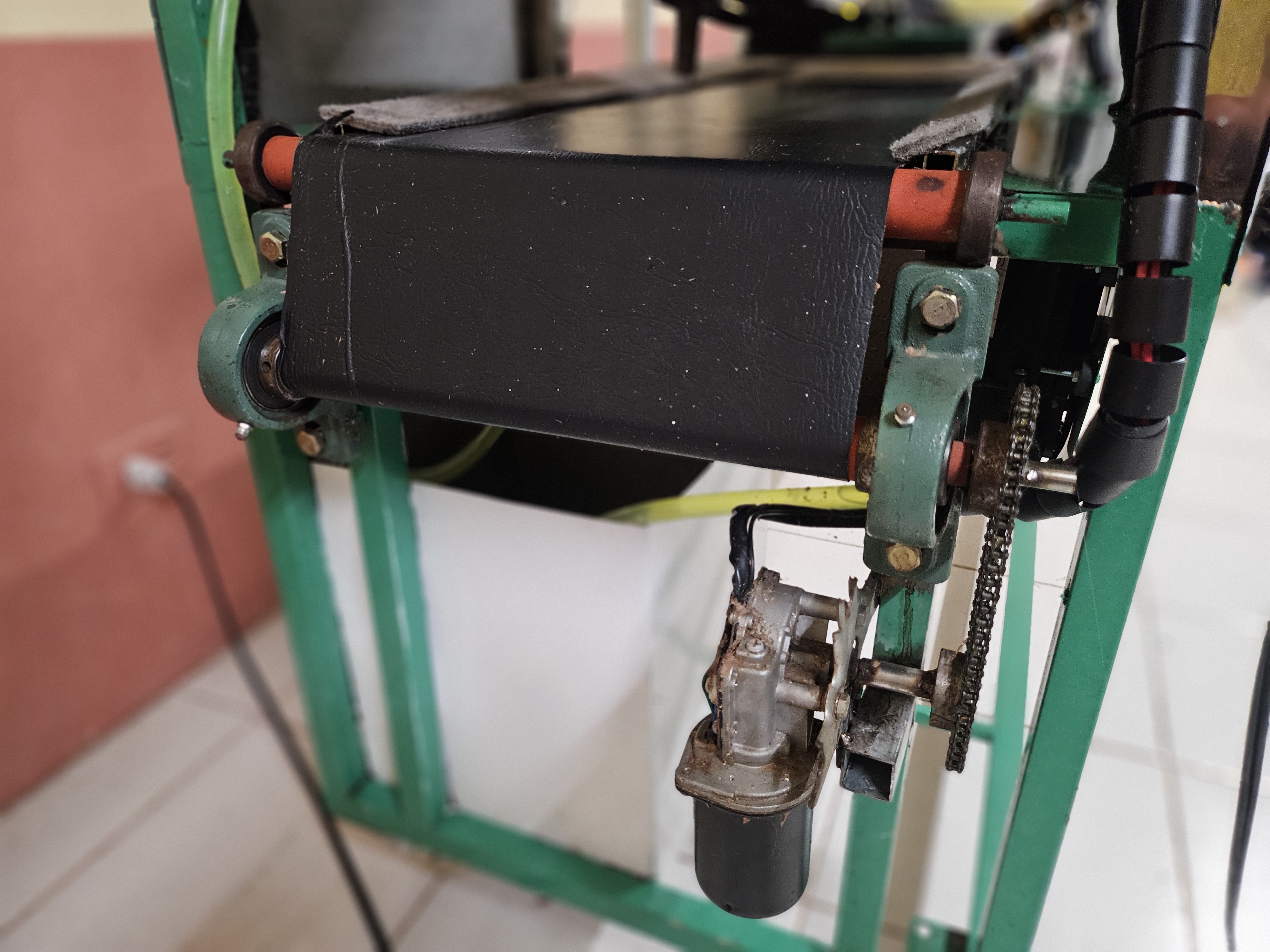

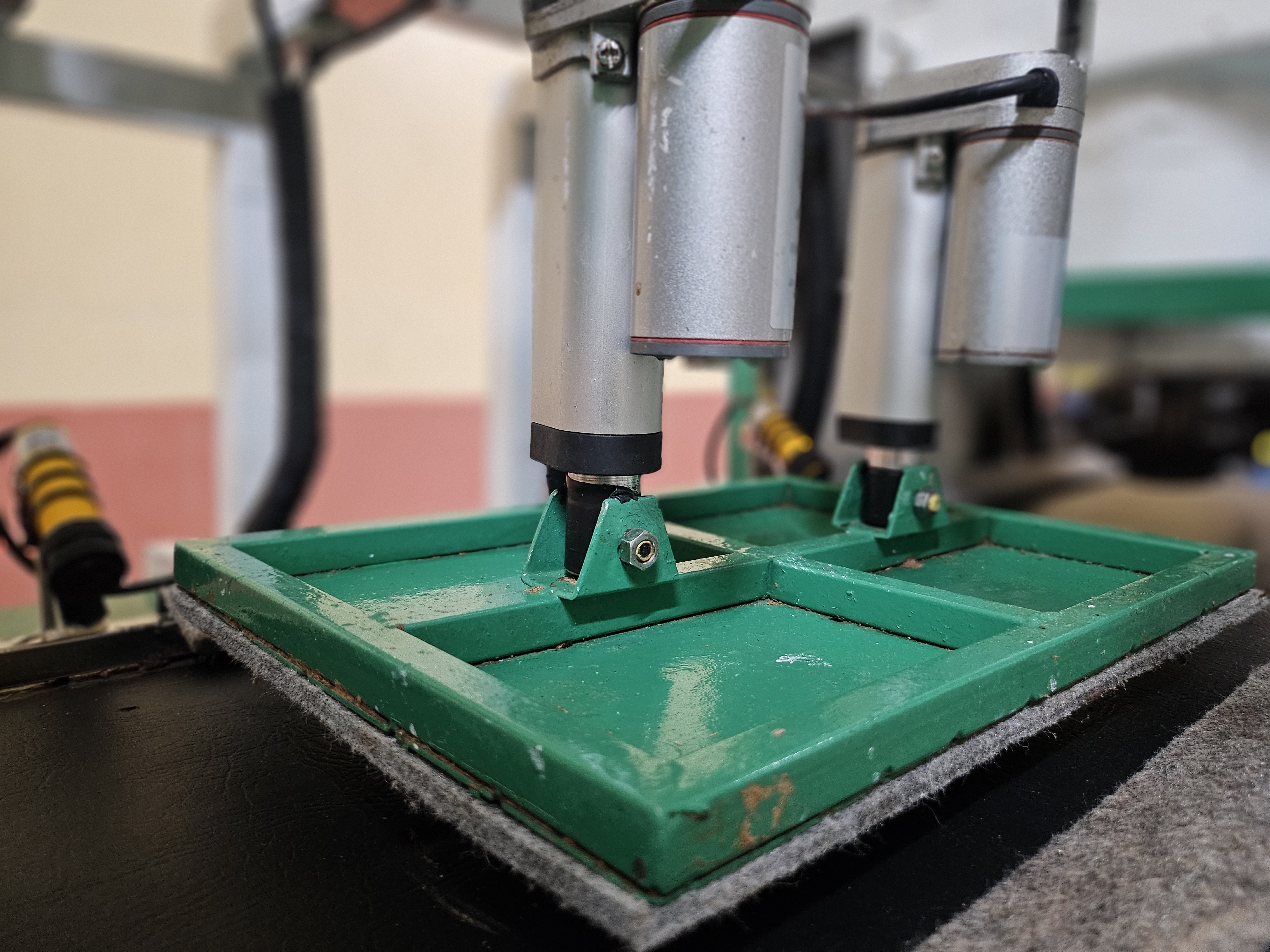

Our innovative machine breathes new life into fallen dry leaves by transforming them into sustainable paper, powered by IoT automation.

More than a process—it's a movement against deforestation, waste, and pollution. Join us as we re-envision what nature's leftovers can become—because every leaf deserves a second life.

100%

Natural Materials

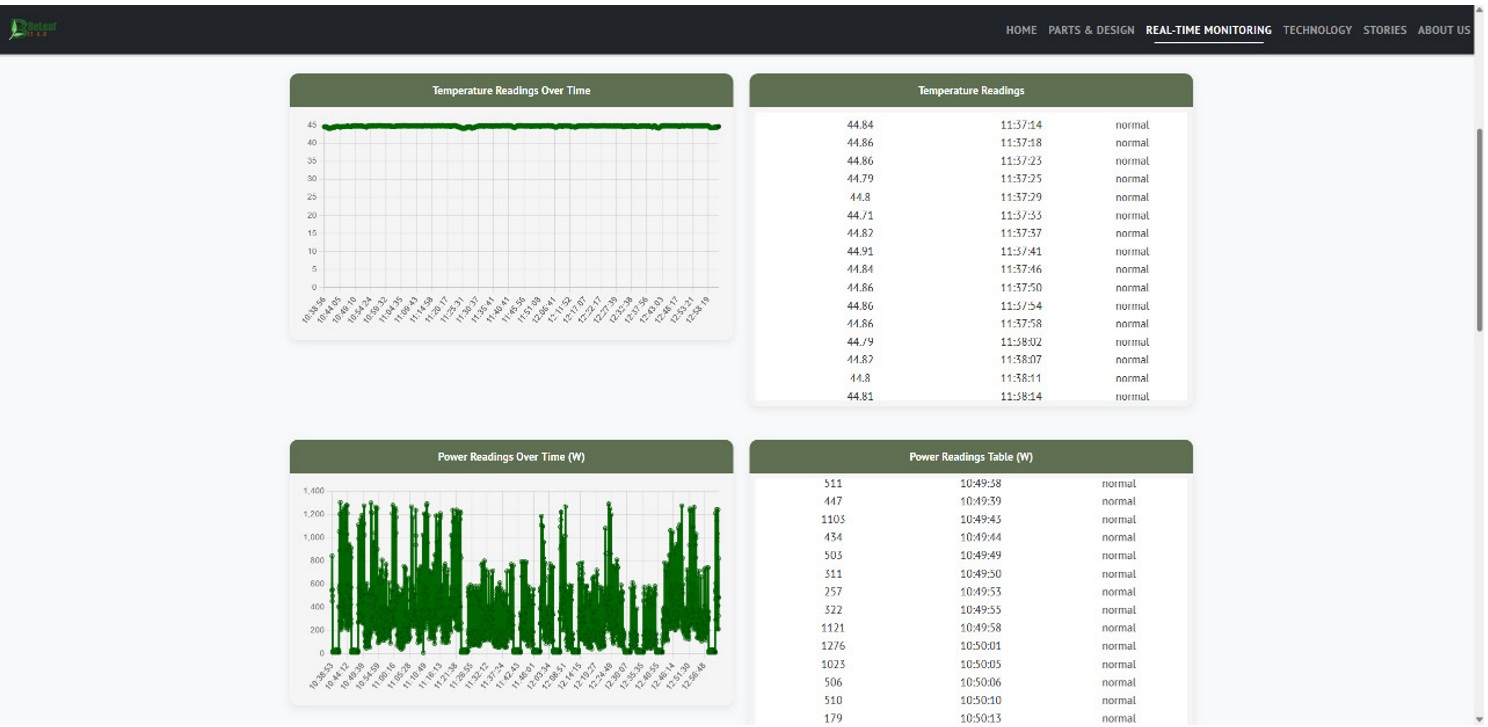

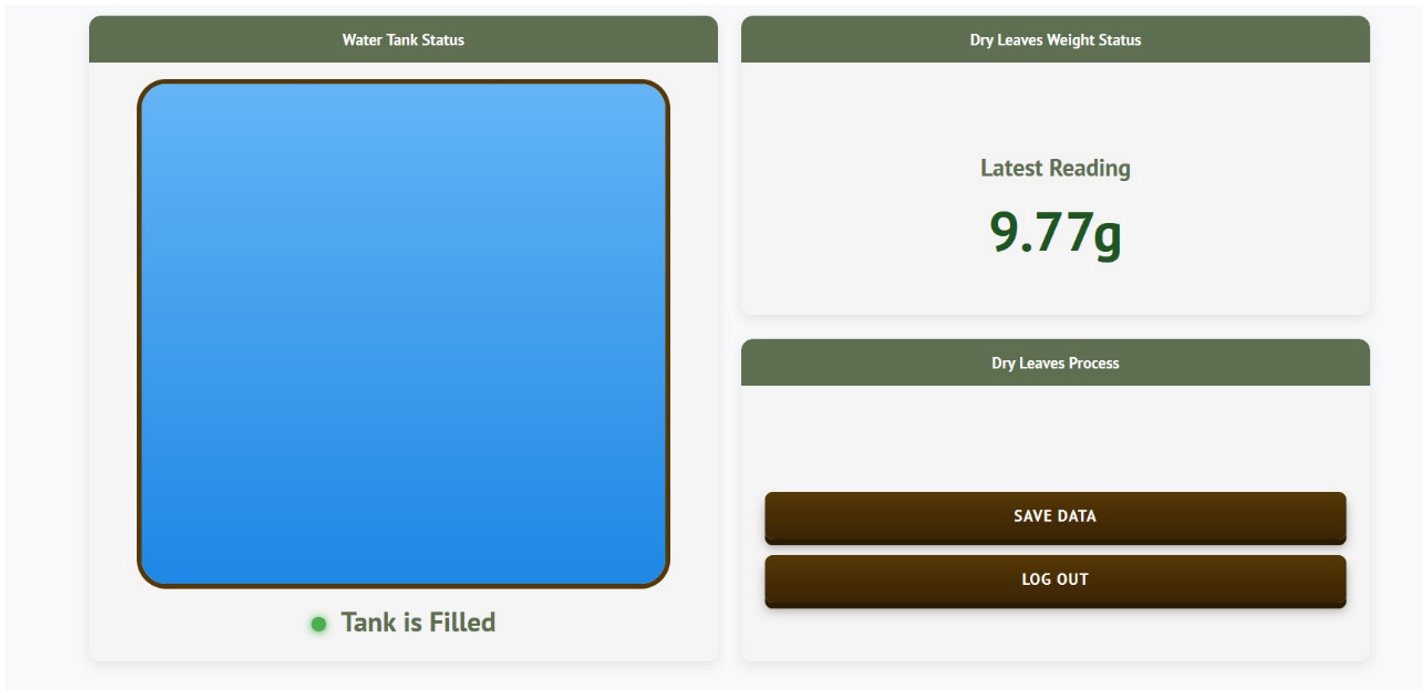

24/7

IoT Monitoring

0%

Chemical Waste